Fabled Copper Corp. Reports on the Davis Keays UAV Drone Mission Survey

posted on

Apr 27, 2022 11:58AM

Developing the Muskwa Copper Project in Northern British Columbia + Reports 23.40% Copper on South Extension of Eagle Creek Copper Occurrence

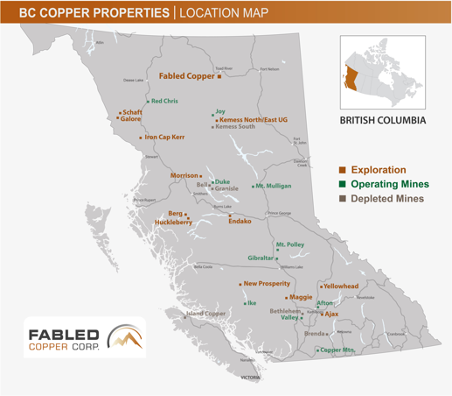

Fabled Copper Corp. ("Fabled Copper" or the "Company") (CSE:FABL) (FSE:XZ7) announces the results of 2021 surface field work on it's Muskwa Copper Project. See Figure 1 below.

Figure 1 - General Property Location

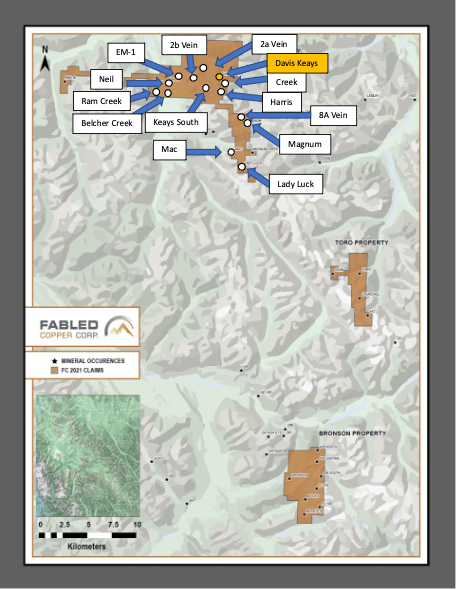

The Project is comprised of the Neil Property and the Toro Property in British Columbia. The Company also holds rights to the Bronson Property. See Figure 2 below.

Figure 2 - Location Map

Peter Hawley, President, CEO reports; "A total of 19 specific areas were mapped and prospected during the 2021 field season and we started the New Year by reporting our findings on the Lady Luck occurrence in the south end of the Neil Property, followed by the Mac; the 8A, Harris, the 2a and 2b, the Creek, Keays south, Belcher Creek, the Magnum Mine UAV Done Mission, the Magnum, the Neil UAV Drone Mission, the Neil, EM-1, Ram Creek and now the Davis Keays Eagle UAV Drone Mission" See Figure 2 below.

Figure 2- Neil Property, Davis Keays Eagle Location

Preamble

Minor follow-up exploration activity took place during the 1950s and early 1960s, with activity increasing significantly during the late 1960s and early 1970s. The work resulted in recognition of numerous copper occurrences within the Neil Property, the most significant of which are the Magnum Vein (Churchill Copper) and the Eagle Vein (Davis Keays). The Lady vein system at the Lady Luck Occurrence also received minor underground development work from 1969 - 1970.

Eagle Vein - Historic Work 1967-1971

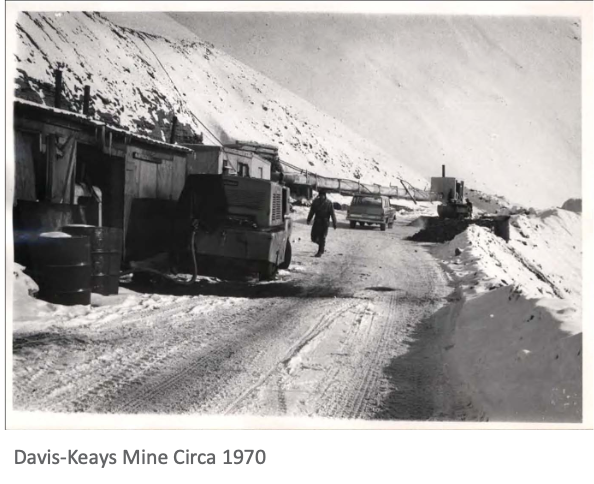

The Eagle and Harris veins at the Davis Keays copper prospect underwent surface and underground development at the same time as the Magnum Deposit from 1969-1971. The Davis Keays Eagle vein is hosted in a northeast-trending vertically-dipping quartz-carbonate shear zone that has been explored by underground development over a strike length of approximately 1,220 meters and to a depth of 460 meters. Over 22,905 feet (6,982 meters) of underground work was completed that included drifting, cross-cutting, and raising (Harrington, 2021). Drifting on the Eagle vein was carried out at four elevations:

Levels 6400, 6950, and 7300 extend completely through the mountain, from Caribou Creek on the west side to Eagle Creek on the east. Approximately 40 000 tons of mined material was removed and subsequently hand sorted in ore and waste piles located at the drift entrance locations (Harrington, 2021). See Figure 3 below.

Figure 3 - Old Davis Keays Eagle Vein Deposit circa 1970

Following a change of ownership in the mid 1970s, Kam Kotia Mines developed approximately 700 meters along the Eagle vein on the 5950-level. The vein was reportedly approximately 3 meters wide and consisted of massive chalcopyrite (Harrington, 2021). Mineralized material from all of the underground work in the area was collected and ~ 58,000 tons of hand sorted mineralized material was shipped to the Bethlehem Copper smelter southwest of Kamloops,BC (Harrington, 2021).

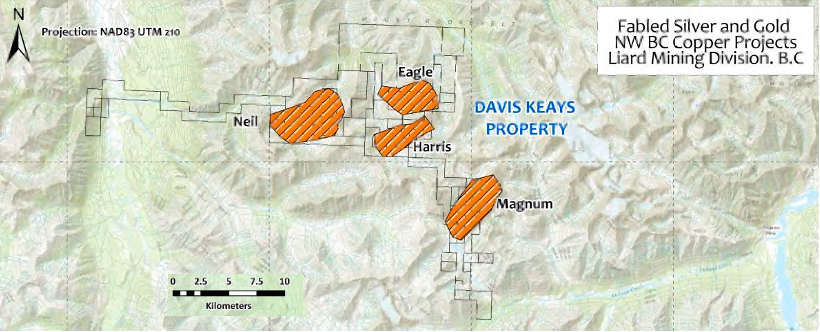

Figure 4 - Davis Keays Eagle Target UAV Drone Survey Area

As part of the 2021 exploration 5 selected areas were surveyed by an Unmanned Aerial Vehicle (UAV) photogrammetry survey was conducted over the Harris, Eagle, Neil and Magnum veins by Drone North, See Figure 4 above for Davis Keays Eagle survey area.

The purpose of the UAV photogrammetry surveys were to:

(i) Generate high resolution photogrammetry datasets for the vein target to better understand bedrock controls on copper mineralization.

(ii) Generate high resolution Digital Terrain Models (DTMs) to assist with 3D modelling of the targets.

(iii) Generate baseline imagery to record current state of surface disturbance at sites that will be actively explored in coming years.

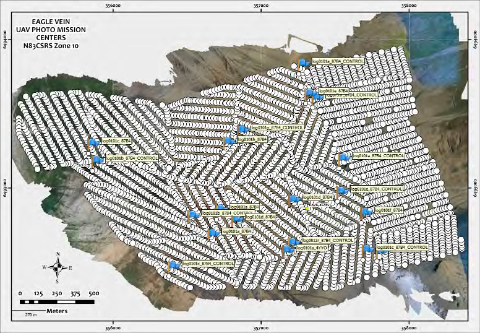

Equipment used to carry out UAV photogrammetry surveys consisted of a DJI Phantom 4 Pro v2.0 optical 20 megapixel camera drone with both a mechanical shutter and an upgraded rover L1/L2 Global Navigation Satellite System (GNSS) receiver. A multi - frequency Sunnav G10 base station was set to allow for PPK corrections of the UAV rover receiver location information. See Figure 5 below.

Figure 5 - UAV Drone Survey Equipment

A GNSS base station was established at the upper-level portal into the underground deposit. Ground control point (GCP) data were acquired during surveying. Sixteen terrain-following missions were completed to survey the Davis Keays Eagle target along with an additional 4 constant altitude missions on the steeper inaccessible eastern slopes. A total of 3,935 photographs acquired during surveying and the final GSD`s (resolution) were 5.78 cm for the orthomosaic and 23.10 cm for the digital surface model (DSM). See Figure 6 below.

Figure 6- UAV Davis Keays Eagle Target Survey Data Points

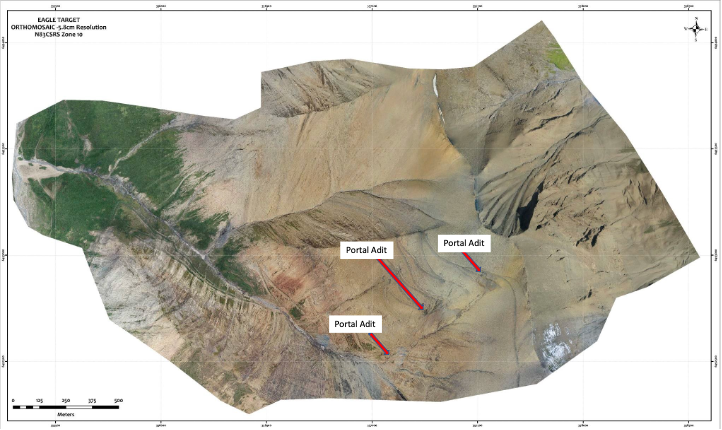

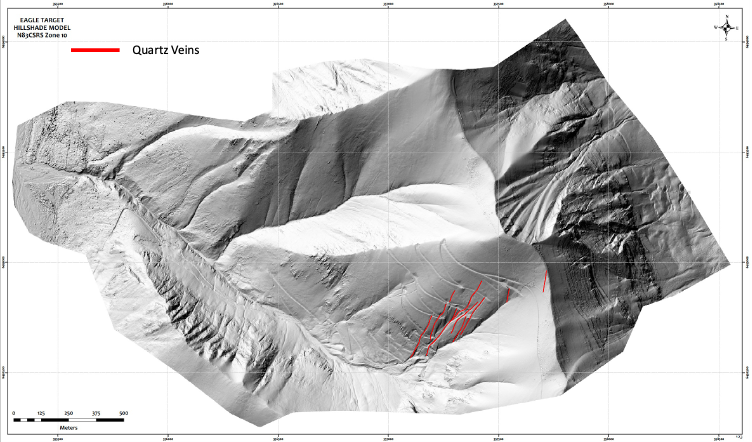

Data products generated include 3-23 cm resolution color orthophoto mosaics, Digital Surface Models (DSM) and Digital Terrain Models (DTM). Hillshade models were also generated for each target area. For the Hillshade model an illumination of 315 degrees was applied. Survey grade accuracy (1-3 cm) ground control point data was also acquired at the time of the UAV survey. See Figures 7, 8 below.

Figure 7- Color Orthophoto Digital Model

Figure 8- Hill Shade Digital Model

The data generated was used for in-field targeting of visual copper occurrences on the color orthophoto due to the 3 cm resolution which lead to field examination of the mineralized unit to sampling of the Magnum vein where a total of 20 samples were collect as a first pass evaluation. Press link here to view Davis Keays Eagle Vein drone flight mission.

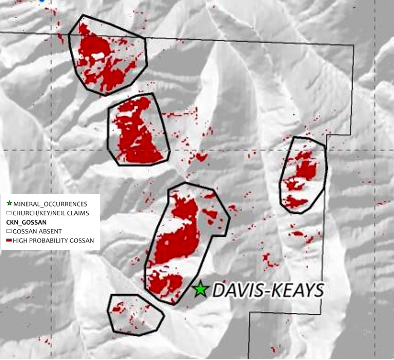

In addition, using various filter parameters, the UAV drone survey area was evaluated for gossan occurrences which could represent alteration of sulphides. The mineral probability map for gossan shows 3 large anomalies occurring in the vicinity of the Eagle vein and to the north of it.

At present it is unsure whether this anomaly is related to alteration or due to elevated iron content in the host stratigraphy. See Figure 9 below.

Figure 9 - 2021 Davis Keays UAV Drone Gossan Anomalies

Going Forwards

Using the results of the data gathered by the UAV drone mission in the 2021 field season the field crew will further sample in detail the Eagle Vein area and ground truth the gossan anomalies.

An additional release on the sampling and results of the Davis Keays Eagle vein deposit will be forth coming in the following weeks.

QA QC Procedure

Analytical results of sampling reported by Fabled Copper Corp represent rock samples submitted by Fabled Copper Corp staff directly to ALS Chemex, Vancouver, British Columbia Canada. Samples were crushed, split, and pulverized as per ALS Chemex method PREP-31, then analyzed for ME-ICP61 33 element package by four acid digestion with ICP-AES Finish. ME-GRA21 method for Au and Ag by fire assay and gravimetric finish, 30g nominal sample weight.

Over Limit Methods

For samples triggering precious metal over-limit thresholds of 10 g/t Au or 100 g/t Ag, the following is being used:

Au-GRA21 Au by fire assay and gravimetric finish with 30 g sample.

Ag-GRA21 Ag by fire assay and gravimetric finish.

Fabled Copper Corp. monitors QA/QC using commercially sourced standards and locally sourced blank materials inserted within the sample sequence at regular intervals.

About Fabled Copper Corp.

Fabled Copper is a junior mining exploration company. Its current focus is to creating value for stakeholders through the exploration and development of its existing copper properties located in northern British Columbia. The Muskwa Project comprises a total of 76 claims in two non-contiguous blocks and totals approximately 8,064.9 hectares, located in the Liard Mining Division in northern British Columbia.

Mr. Peter J. Hawley, President and C.E.O.

Fabled Copper Corp.

Phone: (819) 316-0919

peter@fabledcopper.org

For further information please contact: