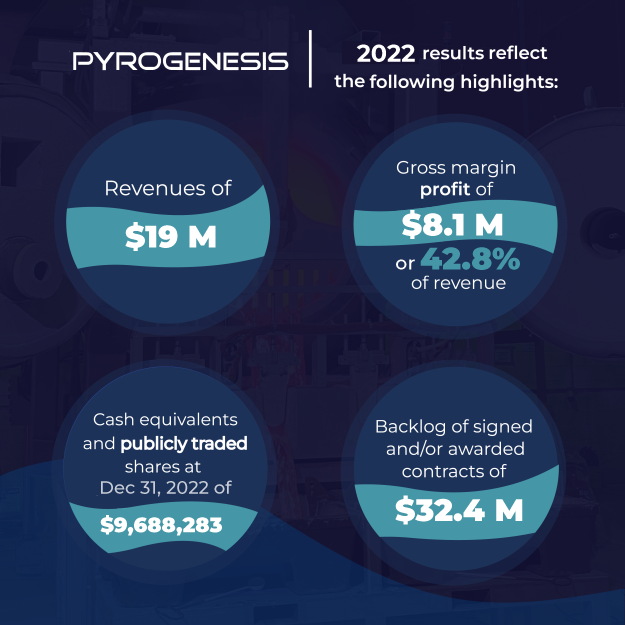

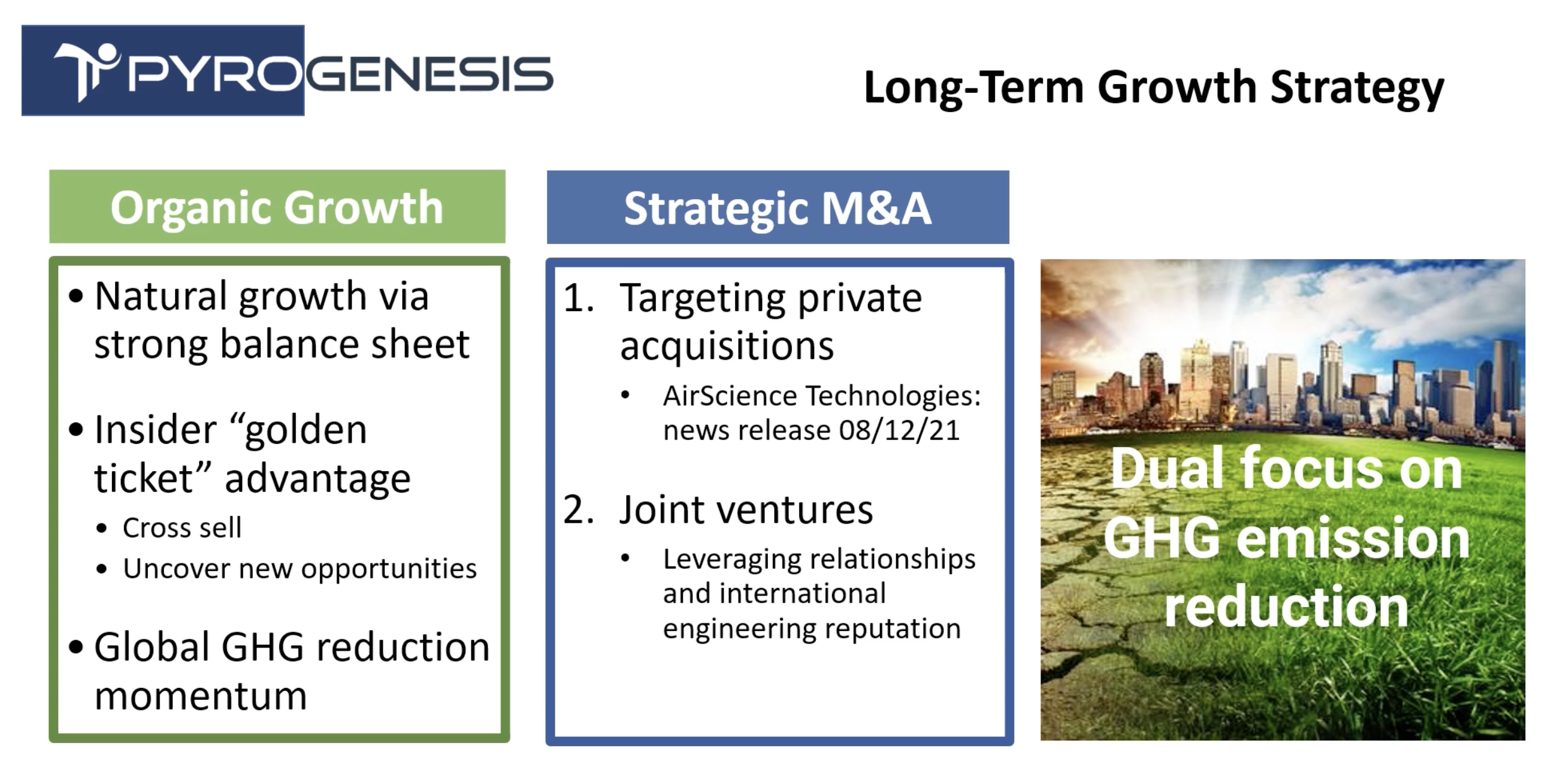

A World leader in advanced plasma processes

Being commercialized in multiple applications around the world including plasma torches, Industrial 3D printing powders, aluminum & zinc dross recovery, waste management and defence - 4 US aircraft carriers

A world leader in the design, development, manufacture and commercialization of plasma atomized metal powders, environmentally friendly plasma waste-to-energy systems and clean plasma torch products.

LINES OF BUSINESS

Powder Production:

- Company expects to see significant year over year improvements in 3D metal powders offering as NexGen™ facility, which incorporates all the previously disclosed benefits (increased production rates, lower capex, lower opex), is now on-line.

- There are major top tier aerospace companies and OEMs, in both Europe and North America, eagerly awaiting powders from this new state-of-the-art production line

- Currently in the process of supplying sample powders to them for analysis.

- Of note, a major tier one global aerospace company entered into an agreement with the Company to qualify its powder, at considerable expense to the global aerospace company, with a view towards having the Company become a supplier.

- Company expects that such developments will continue and will translate into significant improvements in contributions to revenue by this segment in the mid-long term.

DROSRITE™:

- Company continues to aggressively explore horizontal growth opportunities.

- The Company is currently bidding on an up-stream opportunity valued at approximately $40MM.

- This process is plasma based, and not only reduces GHG, but seems to be cheaper than alternate technologies.

- This project is located in the Middle East and is currently experiencing delays to allow the processing of government documentation to catch up with the bidding process.

- PYR has 14 Drosrite™ systems either installed/in shipping or new ordered/requested, of which eleven (11) have been completed and are either on-site at the clients’ facilities or in the process of being shipped.

HPQ:

- PUREVAP™ "Quartz Reduction Reactors" (QRR): PyroGenesis has developed the GEN3 PUREVAP™ QRR pilot plant, which has undergone successful process testing. The pilot plant operates as designed and produces silicon (Si) materials. The produced silicon exceeds the 99.5% purity threshold, which is the best commercially available purity level. The pilot plant has also achieved semi-continuous batch production milestones.

- Silicon-Based Battery Material Production Line: HPQ, in collaboration with PyroGenesis, is in the early-stage planning for a silicon-based battery material production line in North America. They aim to utilize the 2,500 tonnes per year (TPY) of high purity silicon produced by the Gen4 PUREVAPTM Quartz Reduction Reactor as feedstock for the battery material production line and other applications.

- Delivery of Silicon Material Samples: HPQ has delivered the first batch samples of micron-sized 4N+ silicon powder materials to a world-leading high-performance material company. The 4N+ silicon is an essential material used as feedstock to produce high-value silicon materials like silicon nitride.

- Progress in PUREVAP™ QRR Pilot Plant: The testing of the GEN3 PUREVAP™ QRR pilot plant has continued, focusing on stability and predictability for the production of 2N+ silicon, which represents the best commercially available purity in the market. Four production cycles have been completed, resulting in the production of a large liquid silicon bath. The ongoing testing aims to improve silicon production yield and achieve the required purity percentage needed by battery manufacturers and other high-value applications.

- HPQ Fumed Silica Reactor Project: The project has reached its first key milestone. The remaining phases involve completing the fabrication, assembly, and installation of the pilot plant, which is tentatively scheduled to finish by the end of Q3 2023. The pre-commissioning, commissioning, start-up, testing, and process optimization are scheduled to start in Q4 2023 and run until the end of Q2 2024.

Overall, PyroGenesis and HPQ-Silicon have made significant progress in the development of advanced plasma processes and silicon-based materials for various applications, including renewable energy, battery materials, and high-performance materials.

Chemical Warfare Destruction System:

Tests supported the Defense Advanced Research Projects Agency (DARPA) Agnostic Compact Demilitarization of Chemical Agents (ACDC) program

- Successfully completed long-duration performance tests using the Company's tactical Plasma Arc Chemical Warfare Agents Destruction System ("PACWADS") using surrogate chemical warfare agent material

- Far exceeded minimum requirements with over 99.9999% destruction efficiency.

- PACWADS is now scheduled to go through final testing using real chemical warfare agents by the US Military).

Other Contracts:

US Military

- Announced that it should be awarded a two-ship build for its PAWDS unit, for approximately $10MM

- Seeking to establish a presence in the USA to, amongst other things, better serve the US Military’s needs.

- U.S. Navy has reached an agreement with the shipbuilder, Huntington Ingalls Industries (HII), to move forward with the purchase of two Ford-class aircraft carriers.

Torch/Equipment Sales:

PyroGenesis often considers opportunities to leverage its plasma expertise and they continue to review torch technologies which could complement existing offerings and leverage off of their unique relationships. There is nothing currently being discussed that, at this time, has a material probability of being concluded.

12 Month Stock Chart:

Latest Events

- PyroGenesis Announces Minimum $7.5 Million Private Placement of Units, Including Concurrent Placement to CEO

- PyroGenesis Announces Closing of $5 Million Non-Brokered Private Placement

- PyroGenesis Additive Expands European Strategy Team